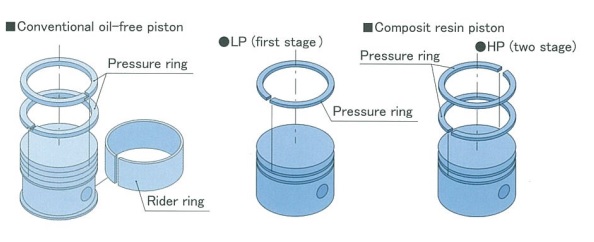

COMPOSIT PISTON FIRST IN THE WORLD.

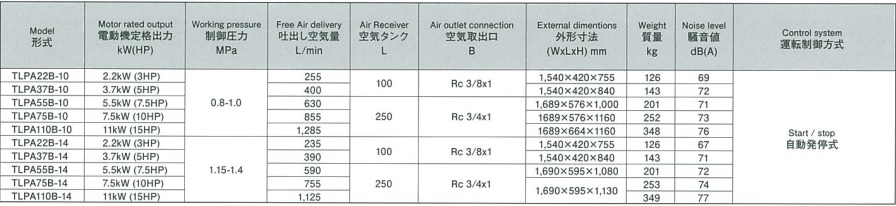

1. Oil-Lubricated Type: TLPA Series

The pressure switch enables simple control.

The pressure switch enables simple control.

Easy to use and economical.

Applications

・Source of air for operating general factory equipment.

・Leisure services.

・Fiber industry.

・Others.

FEATURES

・Low noise: Industry's top-class low noise level. All 1.0MPa models operate more quietly than before.

・Low vibration: Improvement of 2 to 5% in vibration over previous models.

・High efficiency: Improvement of about 5% in efficiency over previous models.

・Low oil consumption: Industry's top-class low oil consumption. A 5% decrease in oil consumption has been achieved from previous models.

・Automatic start-stop system using a pressure switch.

・Air inlet located in front for easy daily maintenance.

For safety considerations, a plastic safety cover is attached to the high-pressure cylinder that can become very hot.

・All the models feature a totally-enclosed fan-cooled motor.

This prevents problems such as damage to bearings due to dust or other waste matter and insulation deterioration caused by moisture.

・The rotating sections are covered by a totally-enclosed belt guard.

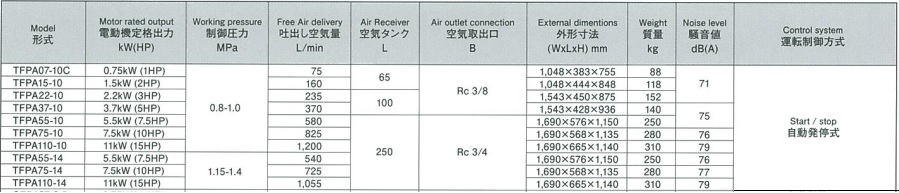

2. Oil-Free Type: TFPA Series

.jpg) The oil-free models provide high-quality clean air.

The oil-free models provide high-quality clean air.

Applications

・Source of air for operating general factory equipment

・Foods and beverages

・Tobacco

・Fiber industry

・Pulp

・Paper processing

・Leisure services

・Painting

・Others

FEATURES

・The composite resin piston prevents seizure and scuffing.

・The oil-free models provide high-quality clean air.

・Recommended for foods, medicine, medical products, printing, painting and other applications that require clean air.

・While oil-free, the models support the maximum pressure of 1.0MPa, accommodating the needs of customers who require high pressures.

・An anti-dust filter kit is featured as a standard component for preventing dust from entering the crank chamber. This helps prevent unexpected problems.

・The oil-free type does not require oil maintenance.

・An anti-dust filter kit is featured as a standard component (TFPA55 and higher) to protect the internal parts.

・The composite resin piston made of heat-resistant thermoset resin endures continuous use at high temperatures and is highly resistant to wear.

・The use of this composite resin piston makes it possible to remove the rider ring required for conventional pistons, eliminating the need to worry about seizure or scuffing that may damage the compressor.

・Also, highly heat-resistant and anti-wear fluorine resin is used in the pressure ring.

3. Oil-Free Type: CFPA Series

Applications

・Source of air for operating general factory equipment.

・Foods and beverages.

・Medicine.

・Dental equipment.

・Air source for machine tools.

・Printing.

・Painting.

・Others.

.jpg)

FEATURES

・Since a self-lubricating composite resin piston is used, there is no need for lubricating oil, resulting in excellent durability without seizure or scuffing. The oil-free models provide high-quality clean air.

・The two-stage compression system (for 5.5kW and higher models) offers high pressures of up to 0.85MPa.

・All the models feature a totally-enclosed fan-cooled motor. This prevents problems such as damage to bearings due to dust or other waste matter and insulation deterioration caused by moisture.

・The oil-free type does not require oil maintenance.

・Functions such as microcomputer control, remote control and multiple unit control are available as options or built-to-made models.

・Low noise levels from 52dB(A) to 59dB(A) are achieved.

・The automatic start-stop system using a pressure switch enables energy-efficient and economical operation (0.75kW to 11kW).