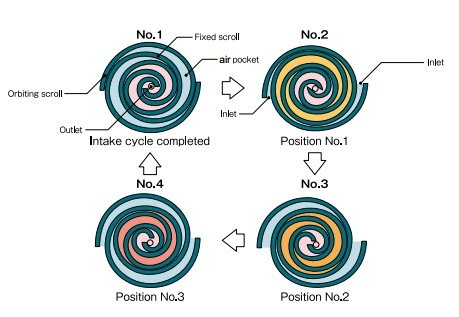

Principle of Compression.

As the orbiting scroll rotates, shown in the illustration from the No.1 position to the No.4 position, crescent shaped air pockets are gradually reduced. At the last stage compressed air is exhausted through the center port.

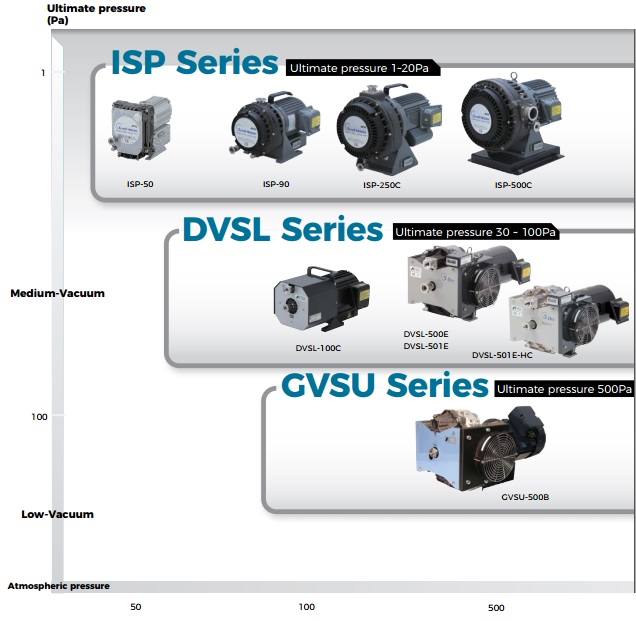

1. ISP Series (Scroll Meister)

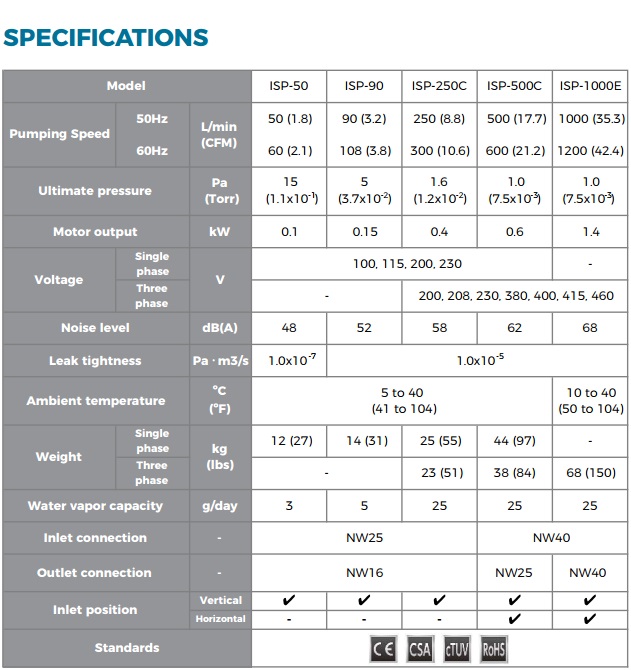

ISP-50/90/250C/500C/1000E

a. Best-selling dry pumps

・Clean exhaust and vacuum

・Easy to use with low vibration and low noise

・Compliant with CE and CSA

・Compliant with RoHS Directive

・Compliant with cTUV.

b. Features.

+ Extensive product lineup:

Five models are available, from ISP-50 to ISP-1000E.

The pumps can deal with a wide range of applications from atmospheric pressure to the ultimate pressure.

These are multi-voltage pumps that can be used with any type of power supply around the world (except ISP-50).

+ Track record proving ANEST IWATA's supremacy:

The dry scroll vacuum pumps are used in various vacuum environments, ranging from the accelerator market to the general-purpose vacuum device market.

These pumps provide clean vacuum without back-diffusion of lubricating oil.

They endure repeated continuous operation between atmospheric pressure and vacuum and are capable of continuous operation near atmospheric pressure.

These features make the pumps best-selling models.

+ Features of scroll-type pumps - low vibration, low noise and high efficiency:

The processes of suction, compression and exhaust proceed continuously with little change in torque, resulting in low vibration and low noise.

The suction chamber and exhaust chamber are not adjacent to each other, making the pumps less prone to leaks and highly efficient.

+ Ease of maintenance:

Since the pumps do not use cooling water or lubricating oil, they are easy to install and maintain.

There is no need to inspect and replace oil filters, lubricating oil, etc.

c. Applications.

■Sputtering equipment, vacuum deposition equipment, ion plating equipment

■Surface modification, electron beam process

■Gas circulation and recovery devices

■Vacuum Pump system

■He leak detector

■Vacuum vacuum chuck

■Accelerator

■Vacuum furnace, vacuum heat treatment furnace

■Laboratory experiments and analyzers

■Vacuum packaging machine

■Others.

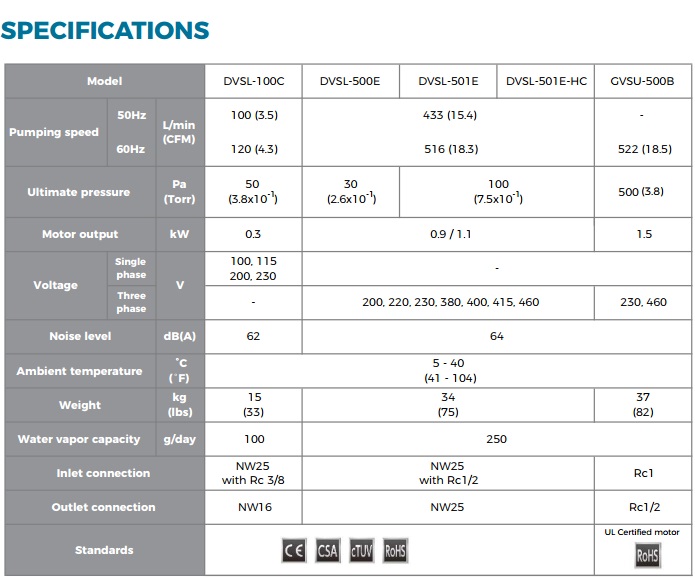

2. DVSL Series (S Dry)

DVSL-100C-B/100C-HCB/500E/501E/501E-HC/1002E

a.Tough dry scroll vacuum pumps.

・Clean exhaust and vacuum

・Resistant to repeated operation between atmospheric pressure and vacuum

・Resistant to water vapor exhaust

・Compliant with RoHS Directive (except DVSL-1002E).

b. Features

With the pumping section containing no lubricating oil or sealing water and no bearing equipped around the part touching gases, these are completely dry pumps that provide clean vacuum and no oil mist.

+ Tough and resistant to water vapor exhaust:

They are tough scroll vacuum pumps that are resistant to continuous operation near atmospheric pressure, repeated operation between atmospheric pressure and vacuum, and water vapor exhaust.

+ DVSL-1002E - Large-displacement multi-stage pump based on DVSL-500E:

The front panel has an hour meter for operation button maintenance and management.

A thermal magnetic switch protects the electric motor.

The air cooling dry scroll system makes daily maintenance easy to do.

The air-flush mechanism makes the pump resistant to water vapor exhaust.

+ Pumps with hard coating launched!

Hard coated pumps with Ni-P surface treatment are now available in the 100L~500L class.

They can be used for water vapor suction and exhaust.

DVSL-100C-HC,DVSL-500E-HC

[Main applications]

■Vacuum condensing, vacuum freeze drying

■Pure water production

■Others

c. Applications.

■Vacuum forming

■Deairator

■Vacuum chuck

■Cryopump roughing and regeneration

■Vacuum cooling

■Vacuum drying only for water based

■Central vacuum equipment

■Ceramic industry

■Gas substitution

■Pumping for electron tube.