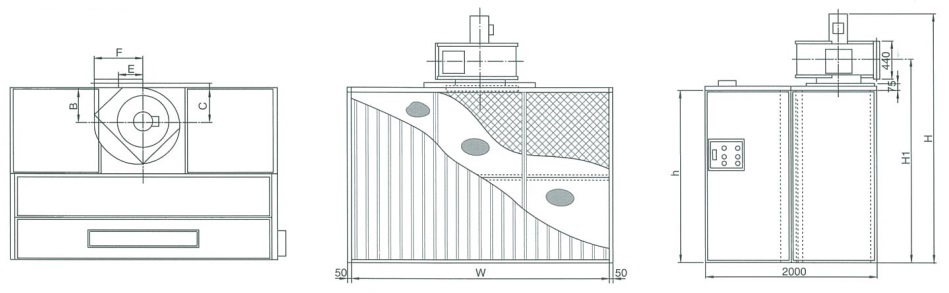

1. Venturi Spray Booth VB Type.

a. Features.

+ Excellent collection efficiency

The swirl chamber system utilizing centrifugal force provides very high efficiency in collecting paint mist: 97% for melamine paint and 96% of plastic paint and lacquer paint (efficiency depends on the property of the paint).

+ Easy model selection based on actual needs

You can choose the most suitable model from among our rich lineup (7 standard models and 28 semi-standard models) based on the installation location and other requirements.

+ Easy cleaning, maintenance, and inspection

・The swirl chamber and return pipe are provided as separate units. What's more, the swirl chamber, which has been made more lightweight, can easily be separated and taken out from the water tank, making it easy to clean, maintain, and inspect the interior of the water tank.

・The cleaning door on the front panel allows the eliminator to be cleaned with ease.

+ Reduction in the exhaust duct installation cost

The number of exhaust fans in large models (VB-40D and 50D) has been reduced to one, resulting in a reduction in the exhaust duct installation cost.

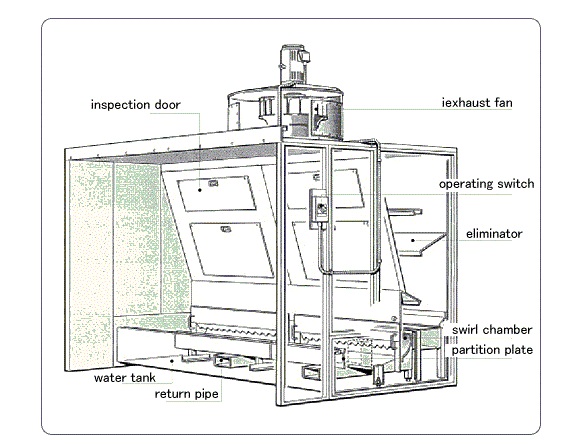

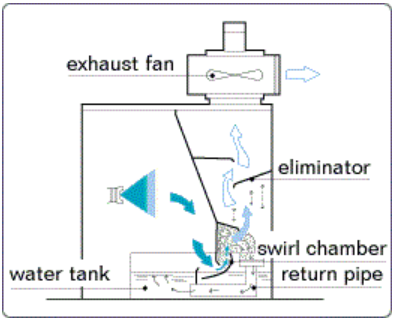

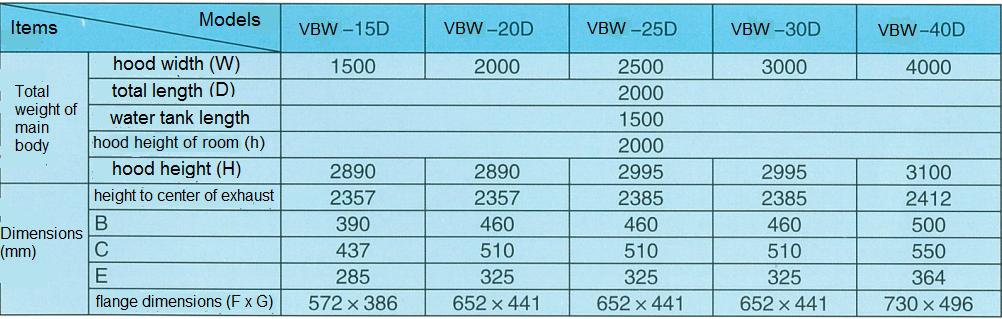

b. Principle of the Collection Mechanism.

The air containing paint mist is drawn at high speed into the swirl chamber by the exhaust fan. The paint mist is separated from the air flow by the centrifugal force of the swirl chamber and collected as it hits the water membrane. The eliminator removes water to prevent it from entering the exhaust port. Water and paint mist are returned to the front of the water tank via

the return pipe.

.png)

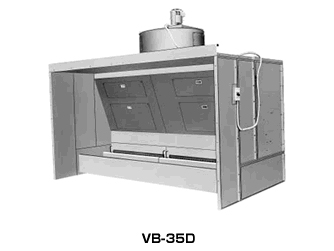

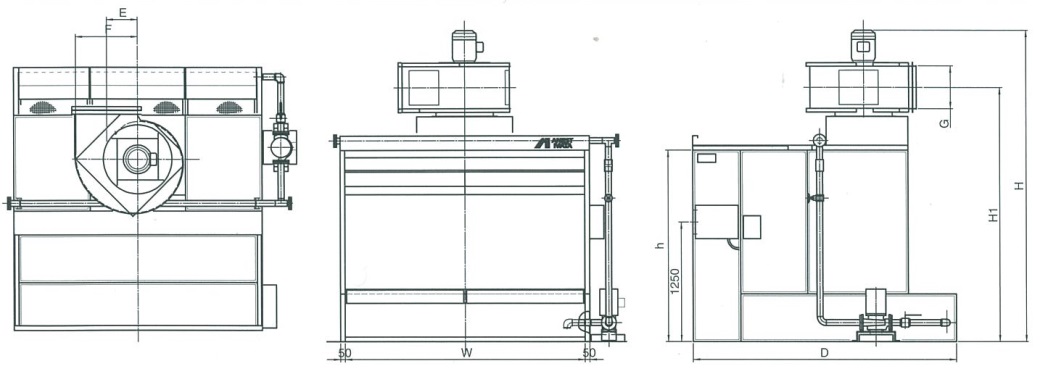

2. Venturi Spray Booth VBW Type.

.png)

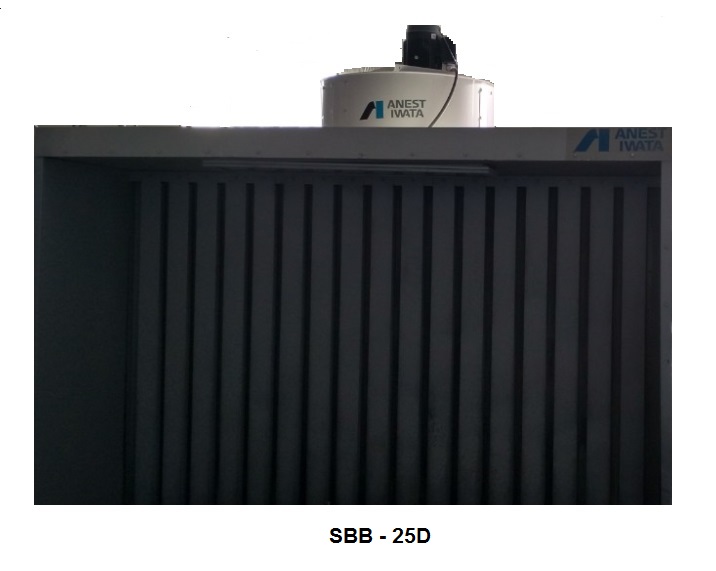

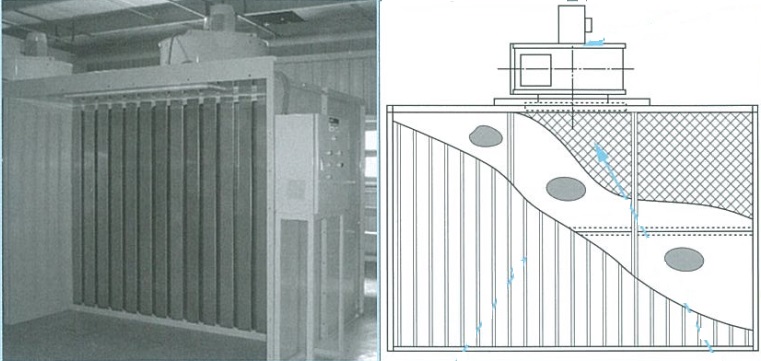

3. Venturi Spray Booth SBB Type.

.jpg)