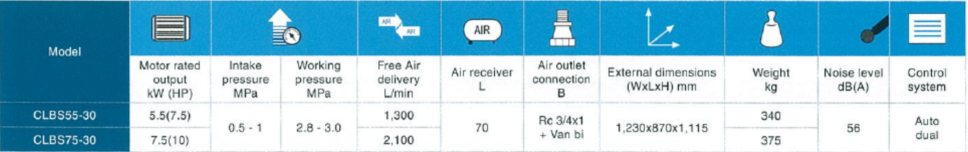

1. Oil-Lubricated Booster Compressor: CLBS Series

High pressures of up to 3.0MPa are offered for a package type compressor.

Features

・High pressures of up to 3.0MPa

・Simple package design

Applications

・Laser processing

・Resin blow molding

・Other high-pressure air supply applications

FEATURES

Quiet package-type compressor (56dB)

・The package-type compressor is a low-noise, low-vibration device, which reduces the noise level at the work site. With its sophisticated simple package design, the compressor can be installed anywhere.

A wide range of pressures can be used.

・The customer can set the pressure arbitrarily within the range from suction pressure to 3.0MPa. This helps prevent the pressure from rising higher than necessary, leading to energy savings.

Easy multiple unit control

・Since multiple units can be controlled, large-capacity applications can be supported. The compressor is ideal for resin blow molding and other applications that require large-capacity high-pressure air.

Piping example for inhaled air

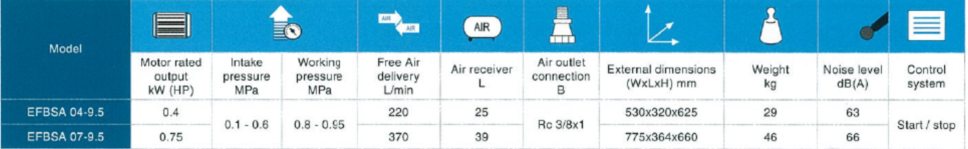

2. Oil-Free Booster Compressor: EFBSA Series

Lowering pressure for energy saving

Why not lower the supply pressure of the compressor?

While 60 to 70% of the equipment used in a manufacturing plant is designed to operate on low pressures, pressures as high as 0.7MPa are typically supplied.

Lowering the supply pressure of the compressor can bring these energy-saving effects:

●Energy-saving effect

The power consumption of the compressor decreases.

●Energy-saving effect

The air consumption (including air leaks) decreases.

●Energy-saving effect

The load of the compressor decreases.

Introducing a booster to compensate for pressure insufficiency after lowering the pressure

| Lower the pressure of the compressor | |

| ↓ | |

| Introduce a booster to compensate for pressure insufficiency | |

| ↓ | ↓ |

|

Boost with air When air-driven booster is used |

When electric-driven booster compressor ESTIBO is used |

|

|

|

When the driving energy is 350 L/min Motor output≒2.6 kW(100L/min→0.75 kW) Power consumption kWh≒3.3 kWh(2.6 kW÷0.8) CO2 emissions ≒7.3 t/year (Operation time 4,000 h/year) More than half of the energy is wasted during boosting. |

When the driving energy is 1.0 kWh CO2 emissions ≒ 2.2 t/year (Operation time 4,000 h/year) Power consumption can be reduced by 70% and air consumption can be halved. Compared to the air-driven type power consumption is reduced to 1/3! |

| ↓ | |

|

Furthermore, the booster compressor ESTIBO reduces CO2 emissions by 5.1 tons annually compared to the air-driven type! |

|

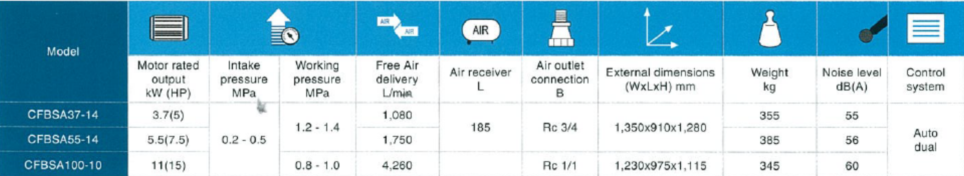

3. Oil-Free Booster Compressor Package Typa: CFBSA Series

The world's first oil-free booster

Features

・Clean air and long life.

・The world's first oil-free booster compressor.

Applications

・Boosting of compressed air.

・Substitute for booster valves.

・Pressure boosting aimed at saving energy after lowering pressure.

FEATURES

The world's first oil-free booster compressor.

・Since a self-lubricating composite resin piston is used, there is no need for lubricating oil, resulting in excellent durability without seizure or scuffing. The oil-free model provides high-quality clean air.

A wide range of pressures can be used.

・Pressure can be set freely within the range of 0.7 to 1.4MPa, leading to energy savings.

Quiet package type.

・The noise level is low - between 55dB and 56dB.

High compression efficiency to provide energy savings through boosting.

・When combined with the lowering of the compressed air line pressure, the compressor can be used as an effective energy-saving system.

Air flow rate

Piping example for inhaled air

The world's first composite resin piston

The composite resin piston made of heat-resistant thermoset resin endures continuous use at high temperatures and is highly resistant to wear.

The use of this composite resin piston makes it possible to remove the rider ring required for conventional pistons, eliminating the need to worry about seizure or scuffing that may damage the compressor.

Also, highly heat-resistant and anti-wear fluorine resin is used in the pressure ring.